New Aluminium Alloy Enables Remote Laser Welding

The new laser remote weldable alloy is a patented multi-layer aluminium sheet product based on Novelis Fusion™. This breakthrough delivers a solution to the industry’s long-time challenge of joining aluminum in automotive production.

One of the latest Novelis’ innovations is the remote weldable alloy Ac-200 RW, which is a unique multi-layer aluminum sheet product based on Novelis Fusion™. This fast-welding aluminium solution was developed specifically to meet automotive industry production needs and delivers advanced welding, design flexibility and better cost effectiveness to the customers.

With Ac-200 RW customers can weld without using filler material, which is typically required for conventional welding methods. Therefore, components can be welded using higher-speed on site improving welding speed three-fold (from 5m/min to 15m/min).

The use of the robot-guided remote laser welding method RobScan increases the welding speed as well as the quality of the welds and the process robustness. In addition, by using the new welding technology, the flange widths can be reduced and thus further weight savings can be achieved. Novelis Ac-200 RW offers car manufacturers significantly greater design flexibility and optimisation of the installation space by allowing them welding components one-sided. This makes assembly easier, especially where limited space is a problem.

All those aspects lead to significantly improved cost effectiveness. Thus, this remote laser welding technology can lower joining costs in car body construction with aluminium remarkably. (Reduced welding customer cost from €1/m to €0.3/m).

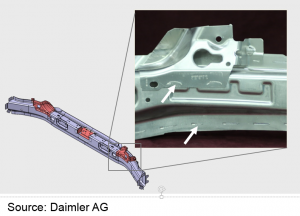

Novelis Ac -200 RW is for the first time worldwide applied in large-scale production in the new Mercedes-Benz S-Class. The seventh generation of the luxury sedan features an aluminium rear center piece based on remote laser welding.

www.novelis.com