| Aluminium recycling in LCA | Declaration by the Metals Industry on Recycling Principles | Environmental Profile Report | Special LCA edition |

Increasing environmental awareness has led to greater use of the Life Cycle Assessment (LCA) methodology and studies.

LCA provides the best framework for assessing the potential environmental impacts of products. LCA deals with product systems which comprise the full life cycle of a product, including raw material acquisition, fabrication, transportation, use, recycling/disposal and the related operations of energy supply, ancillary material supply and transport. ISO 14040 and 14044 standards define the rules and methodologies to consider and integrate properly all stages of the life cycle of a product.

EAA is supporting the use of the LCA tool by presenting reliable life cycle inventory (LCI) data for aluminium applications covering primary aluminium production, the fabrication of semi-finished aluminium products and the recycling of aluminium process and end-of-life scrap:

![]() Environmental Profile Report for the European Aluminium Industry (April 2013)

Environmental Profile Report for the European Aluminium Industry (April 2013)

In addition, the European Aluminium Industry also contributes to the European Platform on Life Cycle Assessment which is developed by the European Commission’s Joint Research Centre. This LCA platform aims at integrating life cycle thinking into product development and into policy making using sound LCA methodologies based on ISO standards.

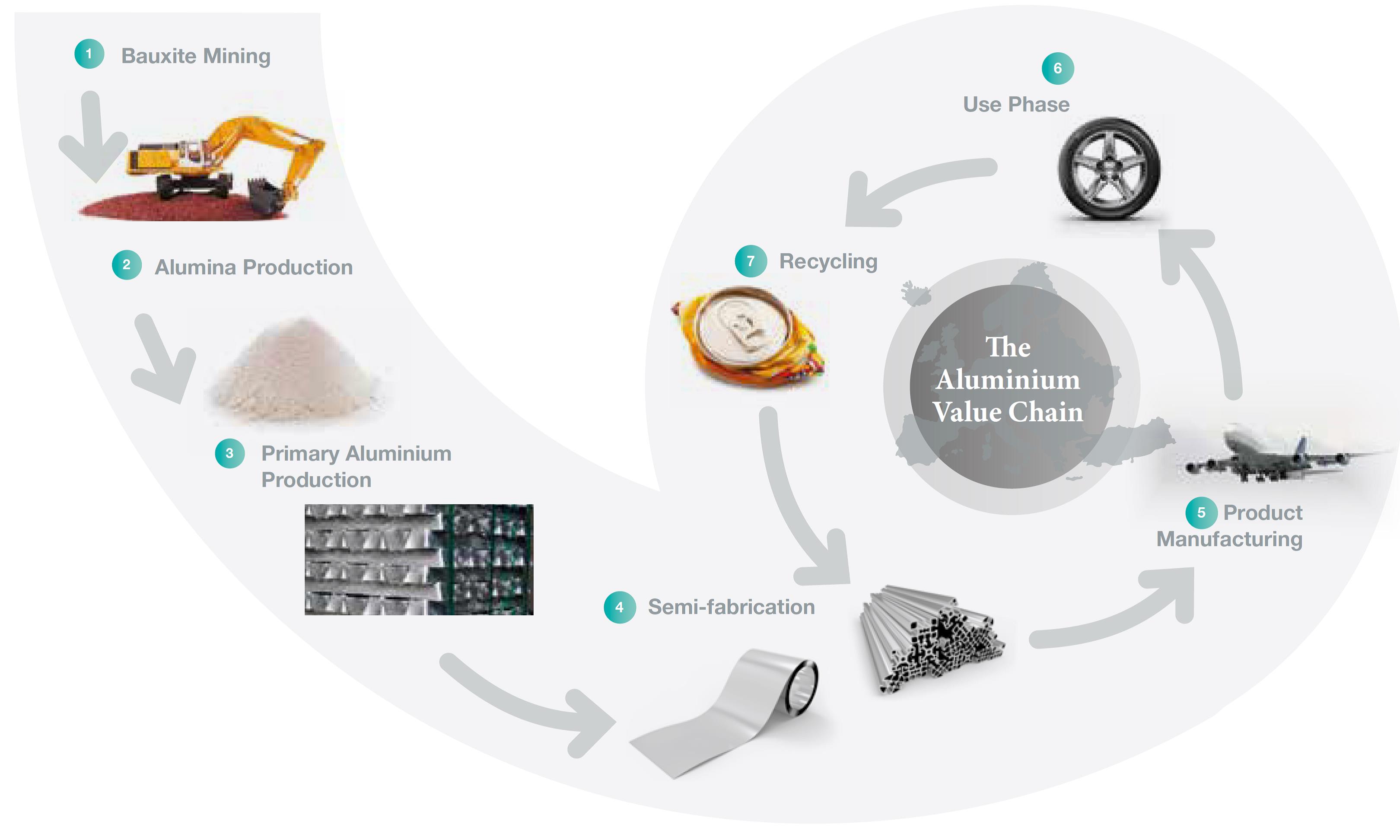

Typical life cycle of an aluminium product

A “cradle to grave” cycle of an aluminium product system can be modelled using different process steps as outlined in the flowchart below. It should be noted that “grave” relates here to the end of life of the product, not of the material aluminium since it is being recycled.