| ROLLED PRODUCTS |

| Return to Production process |

Process description

The starting stock for most rolled products is the DC (Direct Chill semi-continuous cast) ingot. The size of the ingot depends on the size of the DC unit available, the hot rolling mill capacity, volume required for a particular end use and to some extent the alloys being cast. Ingots up to over 20 tons in weight, 500 - 600 mm thick, 2000 mm wide and 8000 mm long are produced.

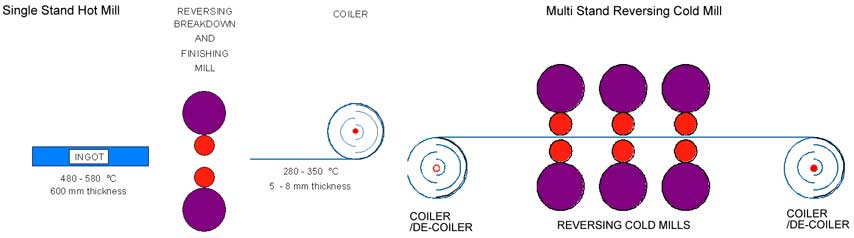

The DC ingot is usually cooled after casting to room temperature and then re-heated to around 500C prior to successive passes through a hot rolling mill where it is reduced in thickness to about 4 - 6 mm (see Figure 1).

| Firgure 1: Hot-rolling principle | Figure 2: Cold-rolling principle |

|

|

The strip from the hot rolling mill is coiled for transport to the cold mill which might be on the same site or elsewhere. Cold mills, in a wide range of types and sizes are available; some are single stand, others 3 stands and some 5 stand (Figure 2). Cold rolling speeds vary but modern mills operate at exit speeds as high as 3000 m per minute and alloys may be cold rolled to thickness of around 0.05 mm.

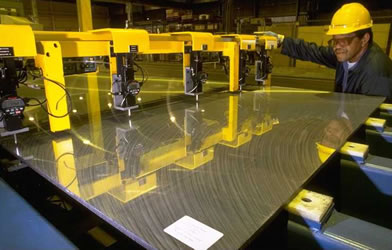

In the past 30 years much effort has been made by the aluminium industry and mill producers to ensure that cold rolled products have the specific characteristics required for satisfactory end use and that they can compete from a cost point of view with competing materials. Properties such as strength, formability, toughness and corrosion resistance are controlled in the main by alloy choice, rolling deformation schedule and thermal treatments, before, during and after rolling. Other requirements such as surface finish, flatness and gauge uniformity have been achieved by careful attention to the mechanics and chemistry of the rolling process. This has been shown to be very important in the production of beverage cans and will play an increasing role in the manufacture of auto-body parts. In hot rolling a knowledge of the influence of the starting stock surface condition, surface condition of the rolls and lubrication used has been necessary, as have the effect of corresponding parameters in the cold mill with the full understanding of the effect of roll coatings, arcs of contact, etc., achieved by very detailed study.